HWT 400 Line

HÜRNER's HWT 400 Line is the end-to-end transformation of worksite technology into workshop systems.

As a consequence, the HÜRNER HWT 400 mm workshop line, too, has systems of the versions CNC (HWT 400 CS), WeldControl (HWT 400 WeldControl), and Manual Hydraulic (HWT 400 M).

All systems have been developed in compliance with the so-called machinery directive 2006/42/EC as amended and allow making segments, tees, Y pieces and crosspieces in workable dimensions from O.D. 90 through 400 mm. The welding systems are set on a welded or a screwed-fast, heavy-duty, no-warp support frame and the bearings on which move both the horizontally traveling carriages and the heating element and facing tool assembly, are designed as precision-engineered and heavy load-bearing trapeze-shaped guides with precision-matched runner blocks.

For the product versions CNC and WeldControl, it goes without saying that all parameters that are critical for a high-quality and reproducible welded joint are monitored throughout the process and saved to the memory of the system, which can hold up to 10,000 reports. Furthermore, all CNC and WeldControl systems are equipped with a USB interface to enable downloading the welding reports in the PDF format to a USB stick or sending them to the management database in the HÜRNER DataWork Professional format. It is also possible to label a joint immediately for its quality by printing on plastic foil an indelible label tag with the available tag printer that will identify the fitting.

Technical Specs

| Technical specs | HWT 400 CS | HWT 400 WeldControl | HWT 400 Manual |

| P/N with cast aluminium clamping jaws | 406-000-004 (metric) 406-000-006 (IPS3)) | 406-000-002 | 406-000-000 |

| P/N with narrow aluminium clamping jaws | 406-000-005 (metric) 406-000-007 (IPS3)) | 406-000-009 | 406-000-008 |

Machine dimensions (W × H × D) | approx. 1100 × 1600 × 1500 mm | approx. 1100 × 1600 × 1500 mm | approx. 1100 × 1600 × 1500 mm |

| Machine weight | 572 kg 2) | 572 kg 2) | 557 kg 2) |

| Power supply | 400 V, 50 Hz, (3 ph., PE) | 400 V, 50 Hz, (3 ph., N, PE) | 400 V, 50 Hz, (3 ph., N, PE) |

| Machine overall rated power | 9000 W | 9000 W | 9000 W |

| Heating element rated power | 5000 W | 5000 W | 5000 W |

| Facing tool rated power | 1850 W | 1850 W | 1850 W |

| Hydraulic unit rated power | - | 1500 W / 120 bar | 1500 W / 120 bar |

| Compressed air | min. 6 bar, max. 14 bar (2:4:2) | - | - |

| Temperature range | 0 °C - 60 °C | 0 °C - 60 °C | 0 °C - 60 °C |

| Heating element temperature | max. 290 °C | max. 290 °C | max. 290 °C |

| Operating range | Segments: 90 - 400 mm Tees: 90 - 315 mm1) Crosspieces: 90 - 315 mm1) Y-pieces: 90 - 315 mm1) | Segments: 90 - 400 mm Tees: 90 - 315 mm1) Crosspieces: 90 - 315 mm1) Y-pieces: 90 - 315 mm1) | Segments: 90 - 400 mm Tees: 90 - 315 mm1) Crosspieces: 90 - 315 mm1) Y-pieces: 90 - 315 mm1) |

| Automatic data logging | 10,000 welding operations | 10,000 welding operations | - |

| Data download | USB ports (USB A) for USB stick and label tag printer | USB ports (USB A) for USB stick and label tag printer | - |

| Standards, approvals, quality | Machinery directive 2006/42/EC, DVS 2207-1, WEEE Reg. No. DE 74849106, ISO 9001:2015 | Machinery directive 2006/42/EC, DVS 2207-1, WEEE Reg. No. DE 74849106, ISO 9001:2015 | Machinery directive 2006/42/EC, DVS 2207-1, WEEE Reg. No. DE 74849106, ISO 9001:2015 |

1) - 355 upon request

2) with cast aluminium clamping jaws; with narrow aluminium clamping jaws, + 85 kg

3) under construction

Literature

Brochures

|

|

|

|

|

|

Certificates

| DIN ISO 9001:2015 | 0.28 MB |

Components

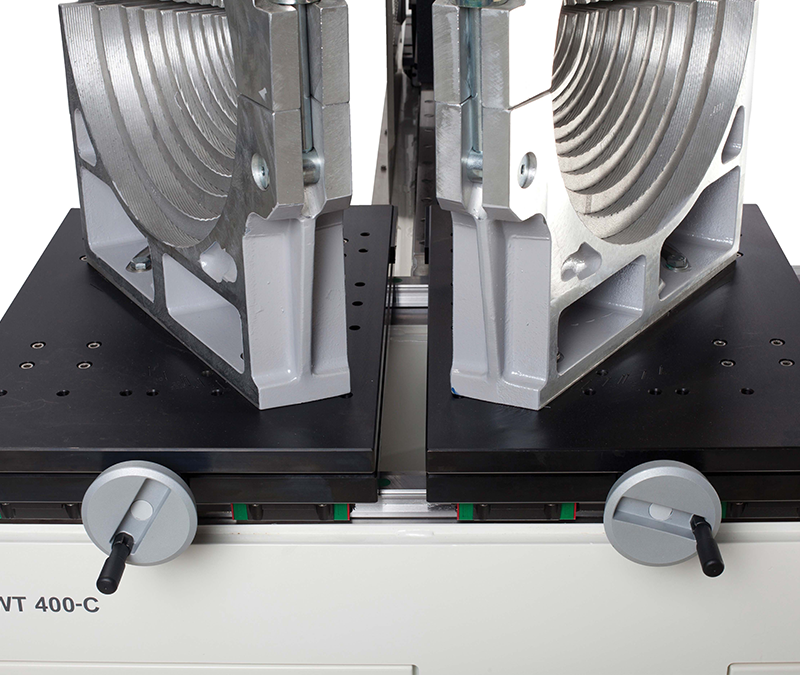

RH side and LH side Clamp

RH side and LH side Clamp

200-260-401 |

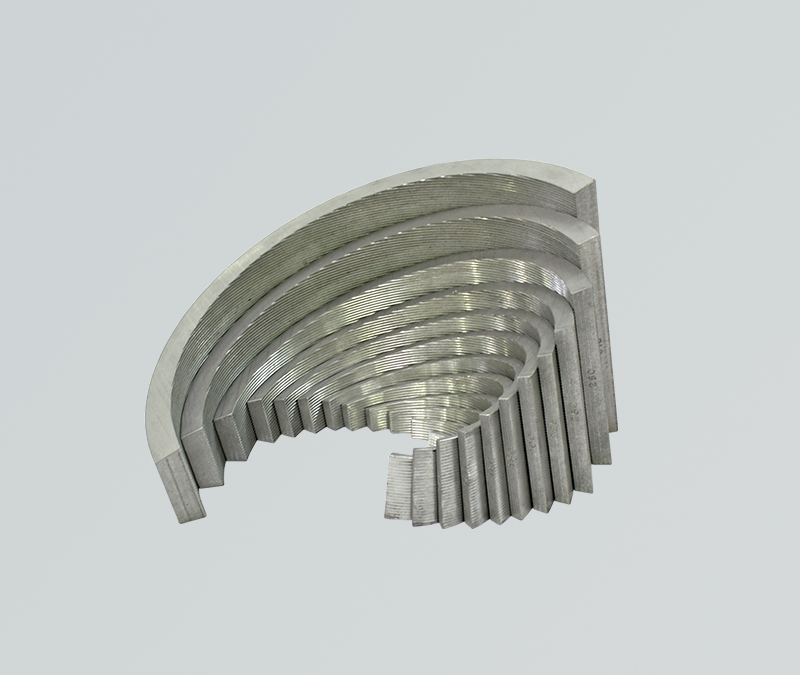

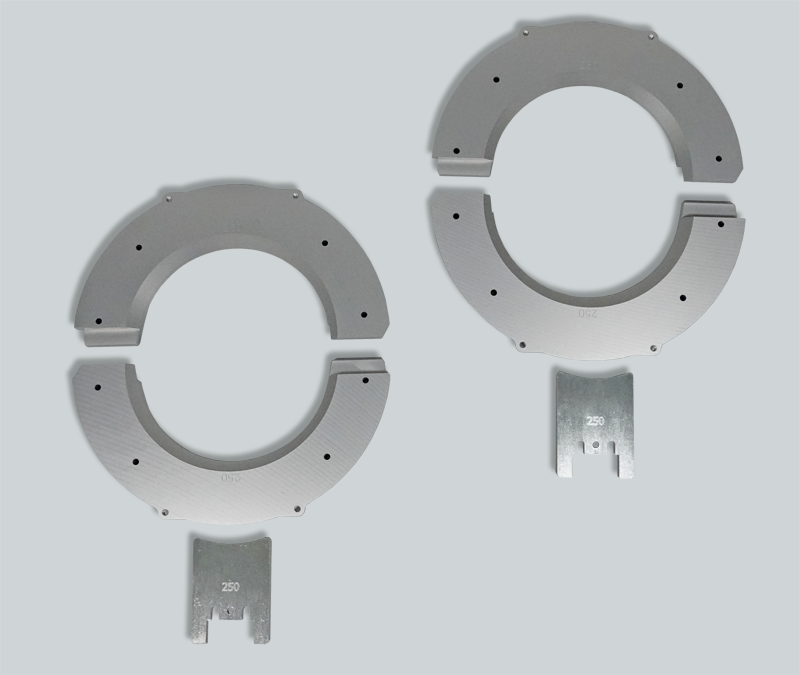

Reducer Inserts for Clamps

Reducer Inserts for Clamps

| 200-260-402 O.D. 90 - 355 mm |

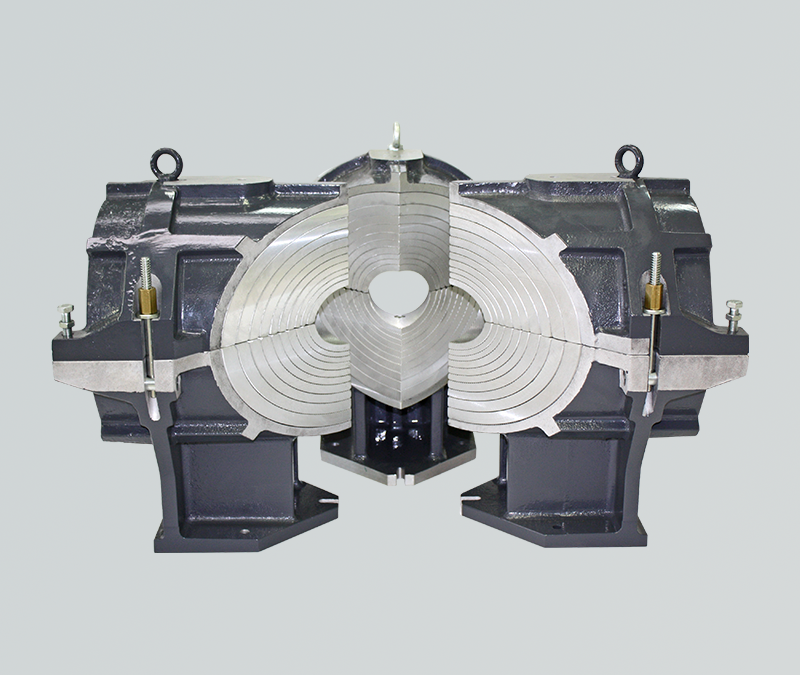

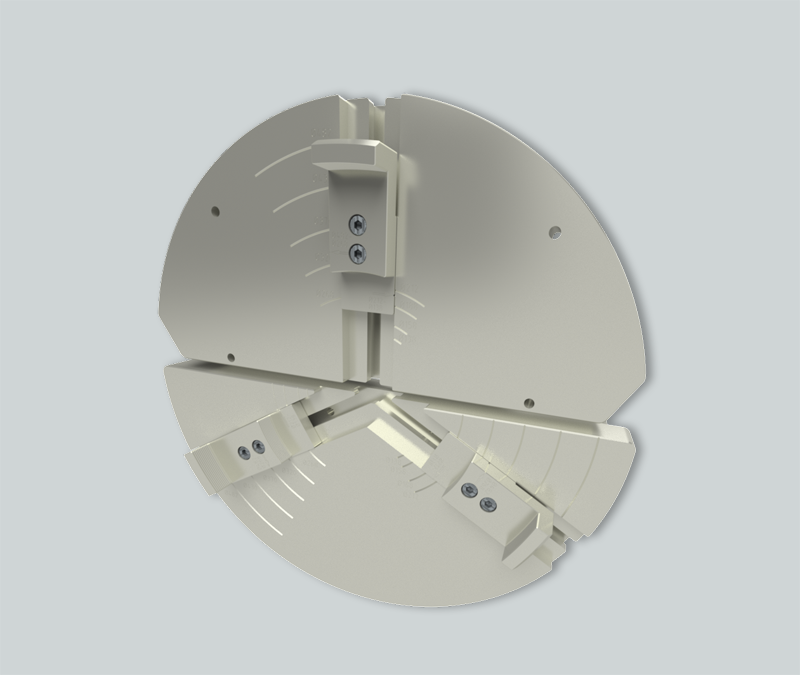

Clamping Jaws for Tees / Crosspieces 90 deg.

Clamping Jaws for Tees / Crosspieces 90 deg.

| 200-260-403 O.D. 315 |

Reducer Inserts for Tees / Crosspieces

Reducer Inserts for Tees / Crosspieces

| 200-260-404 O.D. 90 - 280 mm |

Clamping Jaws for Y-pieces 45 deg./60 deg.

Clamping Jaws for Y-pieces 45 deg./60 deg.

| 200-260-407 O.D. 315 mm |

Reducer Inserts for Y-pieces

Reducer Inserts for Y-pieces

| 200-260-408 O.D. 90 - 280 mm |

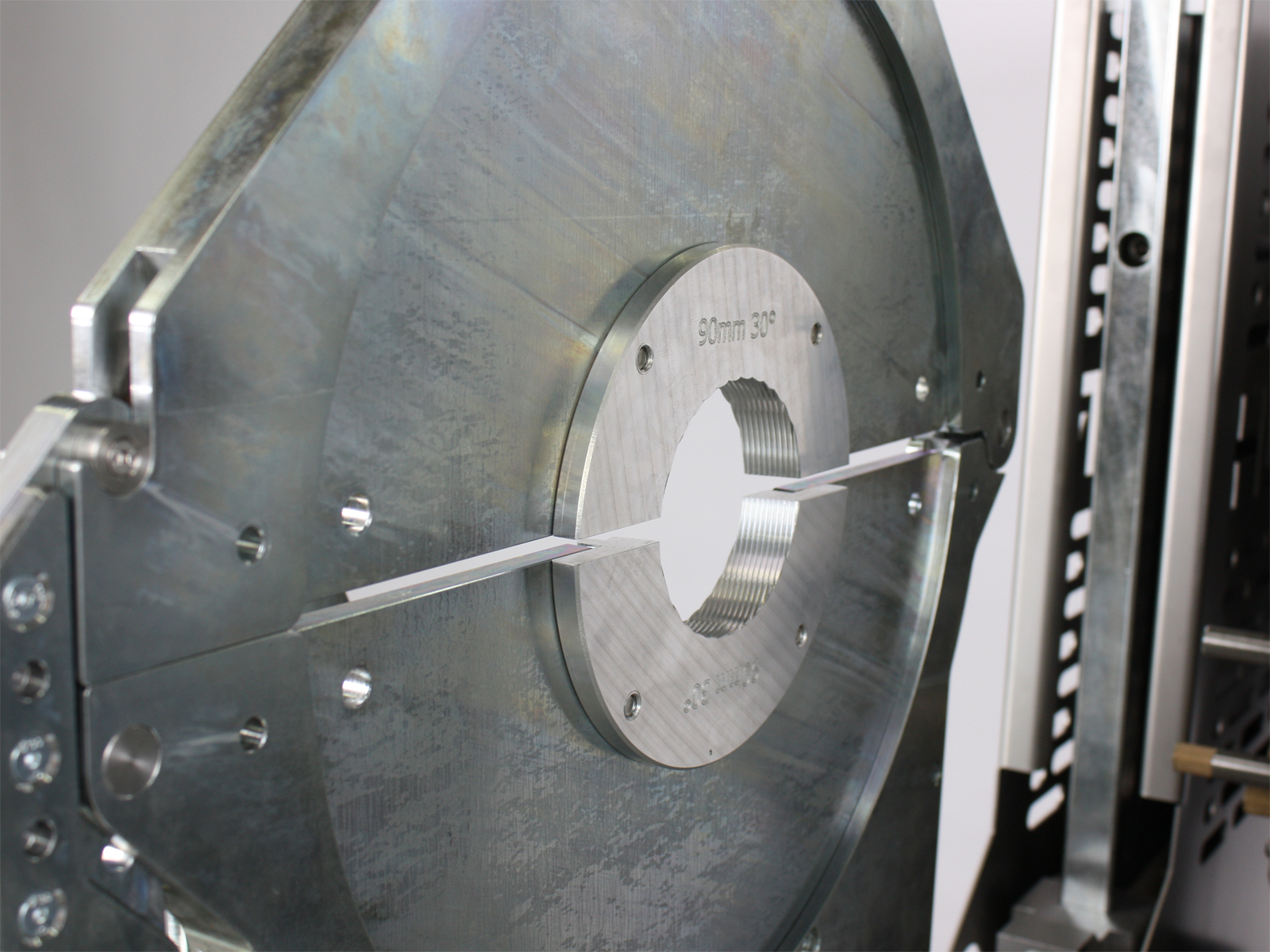

Add-in Reducers for Short Radius

Add-in Reducers for Short Radius

| 406-146-000 Add-in reducers 90 mm for 22.5 deg. | 406-147-000 Add-in reducers 90 mm for 30 deg. | 406-148-000 Add-in reducers 110 mm for 22.5 deg. | 406-149-000 Add-in reducers 110 mm for 30 deg. |

Reducer kit w/ pipe supports

Reducer kit w/ pipe supports

| 406-167-SET Reducer kit w/ pipe supports (steel) O.D. 90 - 355

|

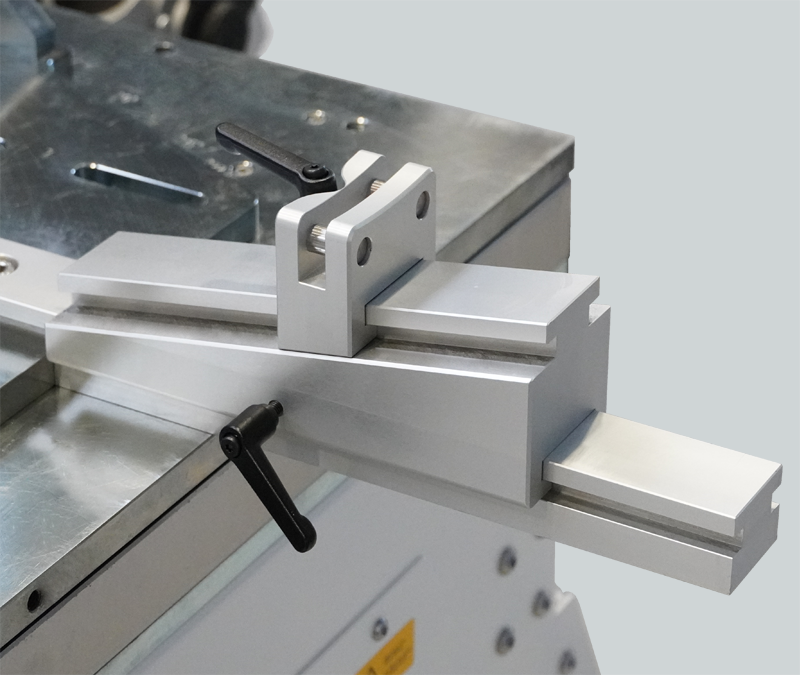

Height adjustable pipe support

Height adjustable pipe support

| 406-151-000 |

Welding Neck Support

Welding Neck Support

| 406-414-000 |

Label Tag Printer

Label Tag Printer

| 200-230-050 |

Tray for Label Tag Printer

Tray for Label Tag Printer

| 404-810-103 |

Tool tray

Tool tray

406-810-035 |

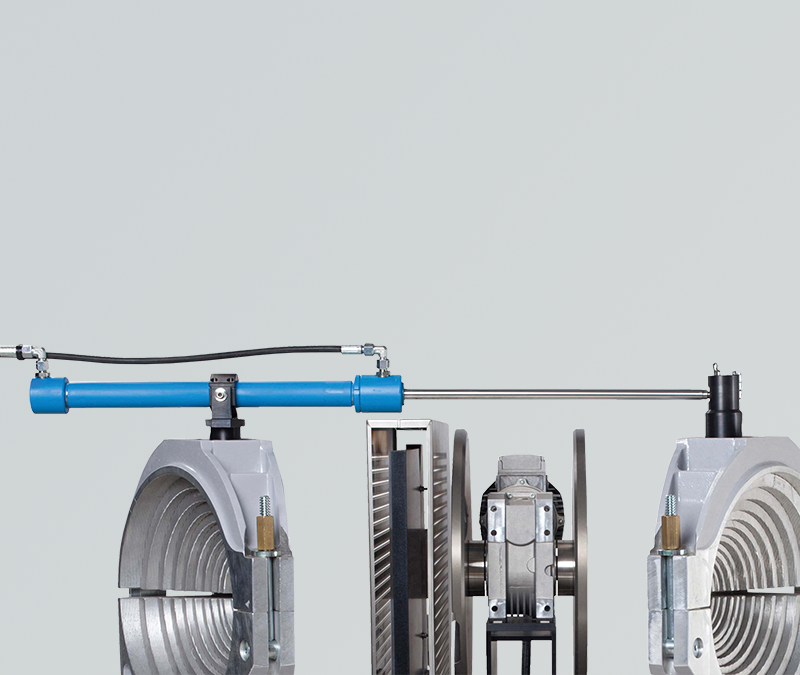

Additional, Reinforcing Cylinder for Clamps

Additional, Reinforcing Cylinder for Clamps

| 200-260-410 |

Additional servo-operated Cylinder

Additional servo-operated Cylinder

| 510-266-000 |

Angle Support Bracket for Components

Angle Support Bracket for Components

| 406-155-000 |

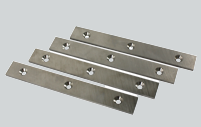

Replacement Blade, 1 pc

Replacement Blade, 1 pc

| 200-600-035 |

Heavy-duty rollers

Heavy-duty rollers

406-820-011 |

Videos